Pan Hand Head Screws: The Ultimate Guide to Their Uses, Types, and Benefits

When it comes to fastening solutions, pan hand head screws are a staple in both professional and DIY toolkits. But what exactly makes these screws so popular? If you’re curious about pan head screws—their design, applications, advantages, and how to choose the right one—this guide will break it all down in simple terms.

What Are Pan Head Screws?

Pan head screws are a type of fastener characterized by their rounded, slightly domed head with a flat underside. Unlike flat or countersunk screws, the pan head sits above the surface, providing a broad bearing surface that distributes pressure evenly.

The design looks a bit like a shallow, flat-topped dome—imagine a small, round pan or skillet, which is where they get their name. This shape is not just aesthetic; it offers specific functional advantages in many applications.

Why Choose Pan Head Screws?

You might be wondering why anyone would pick pan head screws over other screw types. Here are some clear benefits:

- Better Load Distribution: The wide, flat underside spreads out the load, reducing the chance of damage or distortion to the materials being joined.

- Ease of Use: The shape of the head makes these screws easy to grip with tools like Phillips or slotted drivers, speeding up installation.

- Versatility: Pan head screws work well with metal, plastic, and wood, making them a go-to option in countless industries.

- Surface Appearance: Because the head sits above the surface, it can be easier to spot and remove if needed—ideal for maintenance.

Common Applications of Pan Head Screws

You’ll find pan head screws in all sorts of projects and industries:

- Electronics Assembly: Their design helps secure circuit boards without damaging delicate components.

- Furniture Manufacturing: Used to fasten panels and hardware where countersinking isn’t required.

- Automotive: They hold various parts in place with reliable grip.

- Appliance Construction: From microwaves to refrigerators, these screws provide sturdy assembly without compromising appearance.

- General DIY Projects: Ideal for hobbyists and home repairs due to their ease of use and reliability.

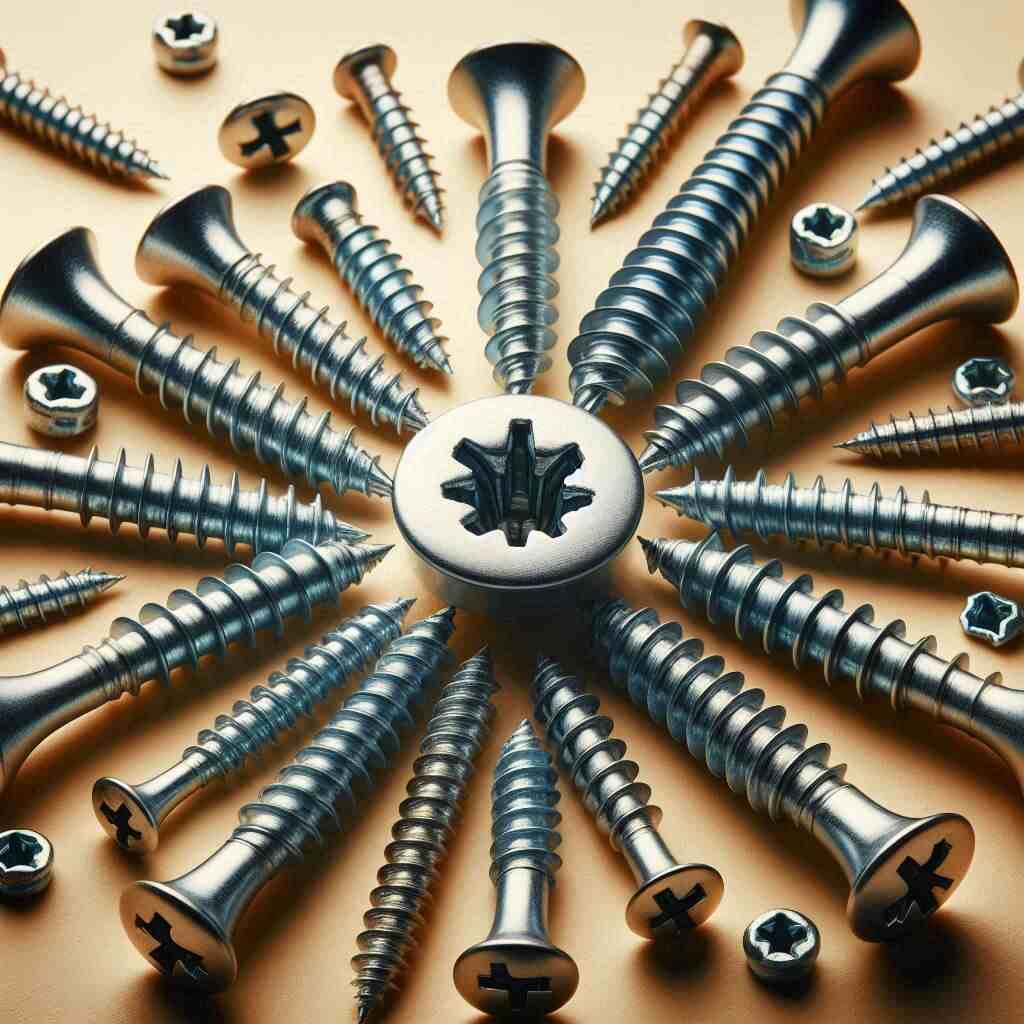

Different Types of Pan Head Screws

While the overall shape remains consistent, pan head screws come in several varieties based on the drive type and threading:

Drive Types

- Phillips Pan Head Screws: The most common, featuring a cross-shaped slot that reduces cam-out and improves torque control.

- Slotted Pan Head Screws: Traditional single-slot screws, simple but less forgiving when it comes to stripping.

- Torx Pan Head Screws: Star-shaped drive that provides excellent grip and torque transfer.

- Hex Pan Head Screws: Have a hexagonal socket for use with Allen keys, common in furniture assembly.

Thread Types

- Coarse Thread: Designed for wood or soft materials, allowing quick installation.

- Fine Thread: Used mainly for metal or hard plastics, offering better hold and resistance to vibration.

- Self-Tapping: These screws create their own thread as they’re driven in, saving time on pre-drilling.

Material Options for Pan Head Screws

The material of the screw affects its strength, corrosion resistance, and suitability for certain environments:

- Steel: Strong and affordable but prone to rust unless coated.

- Stainless Steel: Resistant to corrosion and ideal for outdoor or moist environments.

- Brass: Offers good corrosion resistance and is often used in decorative or electrical applications.

- Aluminum: Lightweight and corrosion-resistant, but less strong than steel.

How to Choose the Right Pan Head Screw

Selecting the best pan head screw depends on your specific needs. Here are key factors to consider:

- Material Compatibility: Match the screw material to your project environment (e.g., stainless steel for outdoor use).

- Drive Type Preference: Consider the tools you have available and the risk of stripping the screw.

- Thread Type: Pick coarse or fine thread based on the material you’re fastening.

- Size and Length: Measure carefully so the screw fully secures the parts without going too deep.

- Head Size: A larger head provides more bearing surface but may interfere with other components.

Installation Tips for Pan Head Screws

Want to get the most out of your pan head screws? Follow these handy tips:

- Use the Correct Driver: Match the driver size exactly to avoid damaging the screw head.

- Pre-Drill When Needed: For hard materials, a pilot hole prevents splitting and makes driving easier.

- Don’t Over-Tighten: Stop when the screw is snug to avoid stripping threads or damaging the material.

- Consider Washers: In some cases, washers can protect surfaces and improve load distribution.

Common Mistakes to Avoid

Even with simple hardware like screws, mistakes can happen. Here’s what to watch out for:

- Using the wrong drive type and damaging the screw head.

- Choosing a screw too short or too long for the application.

- Neglecting to pre-drill in hard materials, causing splits.

- Over-tightening, which can strip threads or warp materials.

- Ignoring corrosion resistance in outdoor or wet environments.

How Pan Head Screws Compare to Other Screw Heads

There are many screw head designs—how do pan heads stack up?

- Pan Head vs. Flat Head: Flat heads sit flush with the surface, ideal for countersinking; pan heads sit proud for easier removal.

- Pan Head vs. Round Head: Both have rounded tops, but pan heads have a flatter underside that provides better surface contact.

- Pan Head vs. Truss Head: Truss heads have a wider, lower profile head for a more finished look, while pan heads are taller and more robust.

Maintenance and Removal of Pan Head Screws

One great thing about pan head screws is they’re easy to maintain and remove when needed:

- Use the correct screwdriver to prevent stripping.

- Clean any debris or rust from the head before removal.

- If stuck, apply penetrating oil and allow it to soak in.

- Use a manual driver instead of power tools to avoid damage during removal.

Innovations in Pan Head Screw Design

Modern manufacturing techniques have enhanced pan head screws with features like:

- Self-Drilling Tips: Eliminates the need for pre-drilling.

- Thread-Locking Coatings: Keeps screws tight in high-vibration environments.

- Colored Heads: For aesthetic purposes or easy identification.

Where to Buy Quality Pan Head Screws

You can find pan head screws in hardware stores, online retailers, or specialty suppliers. When buying:

- Look for trusted brands with good reviews.

- Check the specifications to ensure you’re getting the right material and size.

- Consider bulk purchases for cost savings if you need many screws.

Environmental Considerations

Choosing screws made from recycled or eco-friendly materials can reduce your environmental impact. Stainless steel and brass tend to have better recyclability.

Summary: Why Pan Head Screws Are Essential

In summary, pan head screws are a versatile, reliable fastening solution suitable for a wide range of uses. Their unique head shape offers durability and ease of use that makes them a favorite among professionals and DIYers alike.

Conclusion

Pan head screws might seem like a small detail, but they play a big role in construction, manufacturing, and repairs. Their design balances strength, ease of use, and versatility. Whether you’re assembling furniture, working on electronics, or doing general home improvement, understanding pan head screws will make your job easier and more efficient. Next time you reach for a screw, consider the pan head option—you might find it’s just the perfect fit.

Frequently Asked Questions (FAQs)

1. What is the difference between a pan head screw and a flat head screw?

Pan head screws have a rounded top and sit above the surface, while flat head screws are countersunk to sit flush with the material.

2. Can pan head screws be used on wood?

Yes, especially if they have coarse threads designed for wood.

3. Are pan head screws good for outdoor use?

They can be, if made from corrosion-resistant materials like stainless steel.

4. How do I prevent stripping the pan head screw?

Use the right driver bit and avoid over-tightening.

5. What tools are compatible with pan head screws?

Commonly Phillips, slotted, Torx, or hex drivers, depending on the screw’s drive type.

6. Can I use pan head screws without pre-drilling?

Self-tapping or self-drilling pan head screws can be used without pre-drilling, but it depends on the material.

7. Are pan head screws reusable?

Generally, yes, as long as the threads and head aren’t damaged.

8. What sizes do pan head screws come in?

They come in a wide range of sizes, from tiny electronics screws to larger hardware fasteners.

9. Is a pan head screw stronger than a round head screw?

They have similar strength, but pan heads provide better surface contact for load distribution.

10. Why is it called a pan head screw?

Because the shape of the head resembles a shallow pan with a flat underside and rounded top.