Sleeve Anchor: Guide for Secure Fastening in Masonry

Sleeve anchors might not look glamorous, but they’re the quiet heroes that keep balconies safe, handrails sturdy, and shelves right where they belong. If you’ve ever needed to attach something reliably to concrete, brick, or block, this little anchor is the dependable friend you want in your toolbox. In this guide, we’ll break down how sleeve anchors work, how to install them properly, and what to avoid so your project doesn’t just hold—it lasts.

What is a sleeve anchor?

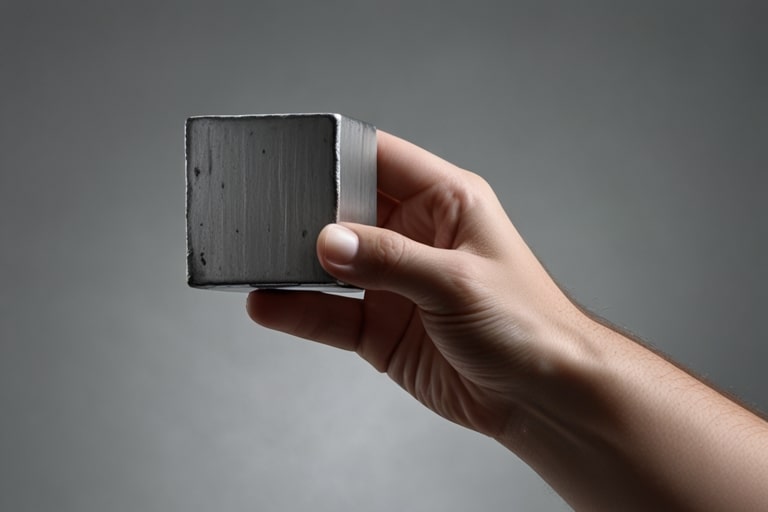

A sleeve anchor is a mechanical expansion fastener designed to secure fixtures to masonry materials like concrete, brick, and concrete block. It’s essentially a bolt surrounded by a metal sleeve. When you tighten the nut or screw head, the sleeve expands against the hole wall, creating friction and mechanical interlock that holds your fixture in place.

How sleeve anchors work

Imagine a wedge pushing outward inside a tight tunnel—that’s the basic idea. As the anchor is tightened, a cone-shaped end pulls into the sleeve. The sleeve expands outward against the walls of the drilled hole, increasing grip and friction. That expansion is what makes the anchor resist pullout (tension) and sliding (shear) forces. The beauty of sleeve anchors is that they’re versatile: they can work in solid concrete and softer materials like brick and block without requiring precise hole conditions.

Key components and design

A typical sleeve anchor includes:

- Anchor body: A threaded bolt with a conical tip.

- Expansion sleeve: A metal sleeve that expands when the bolt is tightened.

- Nut or head style: Hex head, flat/Phillips, or countersunk varieties determine how you’ll drive it and how it sits.

- Washer: Often included to distribute load and protect the fixture’s surface.

The sleeve is the star of the show—it allows the anchor to adapt to slight variations in hole size and base material, making it more forgiving than some other anchors.

Where sleeve anchors are used

Sleeve anchors shine in situations where you need reliable anchoring but the base material isn’t perfect or perfectly uniform.

Common residential applications

- Handrails and stair guards: Secure posts to concrete landings and walls.

- Shelving and storage racks: Attach brackets to garage block walls.

- Outdoor fixtures: Mount hose reels, garden boxes, and light posts to concrete.

- Utility items: Fix electrical conduit straps, junction boxes, and HVAC brackets.

Commercial and industrial applications

- Metal framing and supports: Fasten steel angles and strut channels to masonry.

- Equipment mounting: Secure light machinery, HVAC units, and cable trays.

- Safety barriers and bollards (light duty): Anchor base plates to concrete floors or walls.

- Signage and rails: Install stainless or galvanized anchors for outdoor durability.

Types of sleeve anchors

Different head styles and configurations change how you install and how the finished fixture looks and performs.

Hex head sleeve anchors

- Best for: Heavy-duty applications and easy torque control.

- Why choose: Use a wrench or socket for firm tightening; includes washer for better load distribution.

- Typical use: Handrails, bracketed supports, structural attachments (light-to-medium loads).

Flat head and Phillips head sleeve anchors

- Best for: A cleaner, low-profile look.

- Why choose: Driven with a screwdriver; sits flush against the fixture, ideal where protruding nuts aren’t welcome.

- Typical use: Plates, signage, trim, fixtures that benefit from a simple finish.

Countersunk and round head sleeve anchors

- Countersunk: Designed to sit below the surface when installed in countersunk holes for a sleek, snag-free finish.

- Round head: Offers a finished appearance with an easy drive profile, often used in surface-mounted hardware.

Materials and finishes

Choosing the right material is about matching performance and environment. Anchors don’t live in a vacuum—they live in weather, water, chemicals, and time.

Zinc-plated steel

- Pros: Cost-effective, widely available, good for indoor use and dry environments.

- Cons: Limited corrosion resistance; not ideal for wet, coastal, or chemically exposed settings.

Stainless steel (304 vs. 316)

- 304 stainless: Excellent general corrosion resistance, suitable for most outdoor and damp environments.

- 316 stainless: Superior resistance (thanks to molybdenum) against salt spray and harsh chemicals—your go-to for coastal areas and industrial exposure.

- Trade-off: Higher cost, but potentially cheaper than a failure or replacement later.

Hot-dip galvanized

- Pros: Thick zinc coating for robust corrosion protection in outdoor environments.

- Cons: Not as corrosion-resistant as 316 stainless in marine settings; slightly bulkier threads may feel different during installation.

Choosing the right size and length

Picking the correct size ensures you get a strong, secure hold without damaging the base material.

Diameter options and what they mean

- Common diameters: 1/4″, 5/16″, 3/8″, 1/2″, 5/8″.

- General rule: Larger diameter gives higher load capacity, but requires deeper embedment and more careful spacing.

- Fit and feel: In softer materials (like brick), smaller diameters may grip more reliably; in hard concrete, larger diameters provide superior strength.

Embedment depth and effective anchoring

- Minimum embedment: Follow manufacturer guidance, but a typical rule of thumb is embedding at least 1.5–2 inches into solid material for lighter anchors; more for larger diameters.

- Beyond minimum: Extra embedment can help—but don’t drive so deep that you lose sleeve expansion or hit rebar.

- Base contact: Ensure the sleeve portion sits within solid material. In hollow block, aim to expand in the web or a filled section.

Edge distance and spacing rules

- Edge distance: Keep anchors at least 1.5–2 inches from edges for smaller sizes, and more for larger diameters. Too close and you risk cracking or blowout during expansion.

- Spacing: Avoid placing anchors too close together. Space them at least 10 diameters apart when possible for best performance.

- Pattern planning: For plates or brackets, stagger anchors to distribute load and reduce stress in masonry.

Load capacity and performance factors

Strength isn’t just about the anchor—it’s a partnership between anchor, installation, and base material.

Shear vs. tension loads

- Tension (pullout): Loads trying to pull the anchor straight out of the hole.

- Shear (side load): Loads sliding the fixture sideways relative to the anchor axis.

- Design insight: Most real-world applications see both. Use washers and proper torque to maximize friction and load distribution.

Base material strength: concrete vs. brick vs. block

- Concrete: Offers the highest and most predictable holding strength.

- Brick: Can vary a lot; solid brick holds well, but avoid weak or cracked sections.

- Concrete block: Hollow block needs care—try to seat the sleeve in the web or in a filled cell.

Environmental and corrosion considerations

- Moisture exposure: Corrosion weakens anchors over time, especially near ground level or in wet basements.

- Chemicals: Pools, industrial cleaners, and de-icing salts accelerate corrosion—use 316 stainless or appropriately rated coatings

Tools you’ll need

You don’t need an entire workshop to install sleeve anchors, but having the right tools makes the process faster and safer.

Drilling and hole preparation

- Hammer drill: A must-have for drilling into concrete or masonry. A regular drill may work for softer materials but will take much longer.

- Masonry bit: Always match the bit diameter exactly to the sleeve anchor size. Too small, and the anchor won’t fit. Too big, and you’ll lose holding power.

- Depth stop or tape: To drill consistently to the right depth, use a stop collar or wrap tape around the bit as a depth marker.

- Vacuum or air bulb: Removing concrete dust is essential for good expansion and grip.

Setting the anchor and tightening

- Wrench or socket set: Required for hex head anchors. Choose one that matches your nut size for a secure grip.

- Screwdriver: Needed for flat head or Phillips head sleeve anchors.

- Level: Keeps handrails, shelves, and brackets aligned properly.

- Marker or pencil: To accurately mark drilling points before starting.

Step-by-step installation process

Getting a solid, secure hold is all about following the right process. Here’s how to do it right the first time.

Planning and marking

- Position your fixture: Hold it in place where you want it mounted.

- Mark the holes: Use a pencil or marker to make precise marks through the mounting holes.

- Double-check alignment: Use a level to make sure everything is straight before you drill.

Drilling the hole

- Select the correct bit: Match the bit size to the anchor diameter exactly.

- Drill straight and steady: Use a hammer drill with firm, even pressure. Avoid forcing the bit, which can enlarge the hole.

- Go slightly deeper: Drill a bit deeper than the anchor length to allow space for dust and the anchor cone.

Cleaning and placing the anchor

- Clean the hole: Blow out or vacuum the dust thoroughly—this step is crucial for proper holding power.

- Insert the anchor: Slide it through your fixture and into the hole. Tap it gently with a hammer until it sits flush.

Tightening and verifying

- Tighten gradually: Use a wrench or screwdriver to tighten until snug. Avoid over-tightening, which can strip threads or crack masonry.

- Check for movement: Give the fixture a firm tug. If it shifts, re-check hole size, anchor placement, and torque.

Best practices and pro tips

A few pro tricks can take your installation from “okay” to “rock solid.”

Avoiding blowout and cracking

- Stay at least 1.5–2 inches from edges to prevent cracks.

- Drill at a steady speed to avoid chipping or spalling around the hole.

Ensuring proper alignment

- For multi-hole fixtures, start all anchors before fully tightening any of them.

- Alternate tightening across anchors to spread the load evenly.

Testing for solid holding power

- Lightly pull on the fixture after installation. Any wiggle means you need to troubleshoot before loading it fully.

Sleeve anchors vs. other masonry fasteners

Sleeve anchors are great, but they’re not the only option. Here’s how they compare.

Sleeve anchors vs. wedge anchors

- Wedge anchors offer higher strength in solid concrete but don’t perform as well in brick or block.

- Sleeve anchors are more versatile and easier for DIYers to install.

Sleeve anchors vs. drop-in anchors

- Drop-in anchors are flush-mounted and great for removable bolts but require a special setting tool.

- Sleeve anchors are simpler and allow for immediate installation of the fixture.

Sleeve anchors vs. lag shields and Tapcon screws

- Lag shields require a separate lag screw and work well in softer masonry.

- Tapcon screws are quick but rely entirely on thread cut quality—sleeve anchors are more forgiving and secure under higher loads.

Troubleshooting common problems

Even pros run into hiccups. Here’s how to fix them quickly.

Spinning anchors

- If the entire anchor spins, the hole may be too large. Use a slightly larger anchor or fill the hole with anchoring epoxy and reset.

Oversized holes

- Consider using a wedge anchor, adhesive anchor, or a longer sleeve anchor to engage more material.

Poor holding in hollow block

- Move to the block’s web, use a longer anchor, or switch to a specialty hollow wall anchor designed for block.

Safety and compliance

Never skip safety—your eyes, lungs, and ears will thank you.

PPE and dust control

- Wear safety glasses, gloves, and hearing protection.

- Use a dust mask or respirator, especially when drilling into concrete (silica dust is harmful).

Structural considerations and code awareness

- Check local building codes for handrails, guardrails, and structural attachments—there may be specific requirements for anchor spacing and capacity.

Maintenance, inspection, and removal

Sleeve anchors don’t need much attention, but a quick check keeps them reliable.

Inspecting and re-torquing

- Look for rust, corrosion, or loose nuts periodically, especially on outdoor fixtures.

- Retighten gently if any movement is detected.

Removing sleeve anchors without damage

- Unscrew the bolt or nut, tap the anchor body to release tension, and pull out if possible.

- If the sleeve stays behind, you can cut it flush with the surface and patch the hole.

Real-world examples and project ideas

Need inspiration? Here are some popular uses.

Handrails and guardrails

Perfect for safely securing posts to concrete stairs and landings.

Shelving and utility racks

Strong enough to hold heavy garage shelving or workbench supports.

HVAC and electrical fixtures

Excellent for mounting condenser brackets, conduit straps, and pipe supports.

Buying guide and brand tips

Not all anchors are created equal—here’s how to shop smart.

What to look for on the box

- Confirm base material compatibility (concrete, brick, or block).

- Match diameter and length to your project.

- Check the finish: zinc for dry indoors, galvanized or stainless for wet/outdoor areas.

Trusted brands and consistency

- Choose reputable brands for reliable expansion and thread quality.

- Buy extras—mis-drilled holes happen, and having spares saves trips back to the store.

Conclusion

Sleeve anchors are one of the most versatile and user-friendly masonry fasteners available. They work in concrete, brick, and block, and with the right size, material, and installation method, they can provide years of safe, secure holding power. Whether you’re a DIYer hanging shelves or a contractor installing handrails, sleeve anchors are an essential part of your toolkit. Follow the best practices, use quality anchors, and you’ll have installations that last.

FAQs

- What’s the difference between a sleeve anchor and a wedge anchor?

Wedge anchors are stronger in solid concrete but don’t work well in hollow materials. Sleeve anchors are more versatile and easier for mixed-material jobs. - Do I need to clean the hole before installing a sleeve anchor?

Yes! Dust reduces friction and weakens the hold. Always clean the hole thoroughly. - Can sleeve anchors be reused?

No, they’re typically single-use because the sleeve deforms when tightened. - What’s the best material for outdoor projects?

Stainless steel (preferably 316) is best for outdoor or coastal environments due to superior corrosion resistance. - How do I prevent cracking near the edge of concrete?

Maintain proper edge distance (at least 1.5–2 inches) and tighten gradually to avoid excessive stress.