Strut Clamp Guide: Types, Uses and Installation Tips

If you’ve ever watched a contractor hang pipes, cable trays, or HVAC lines, you’ve probably seen strut clamps in action — the unsung hardware heroes that keep everything tidy and secure. But what exactly is a strut clamp, which type should you pick, and how do you install one without turning the job into a headache? This guide walks you through everything: types, materials, installation steps, common mistakes, and practical tips so you can pick and use the right clamp every time.

What is a Strut Clamp?

A strut clamp is a fastening device designed to secure pipes, conduits, cables, or other components to a metal framing system commonly called a “strut channel” or brand names like Unistrut. Think of the strut channel as a Lego rail and the clamp as the Lego piece that locks your pipe to the rail — modular, adjustable, and reusable. Strut clamps come in many shapes and sizes so they can handle anything from a light conduit to a heavy process pipe.

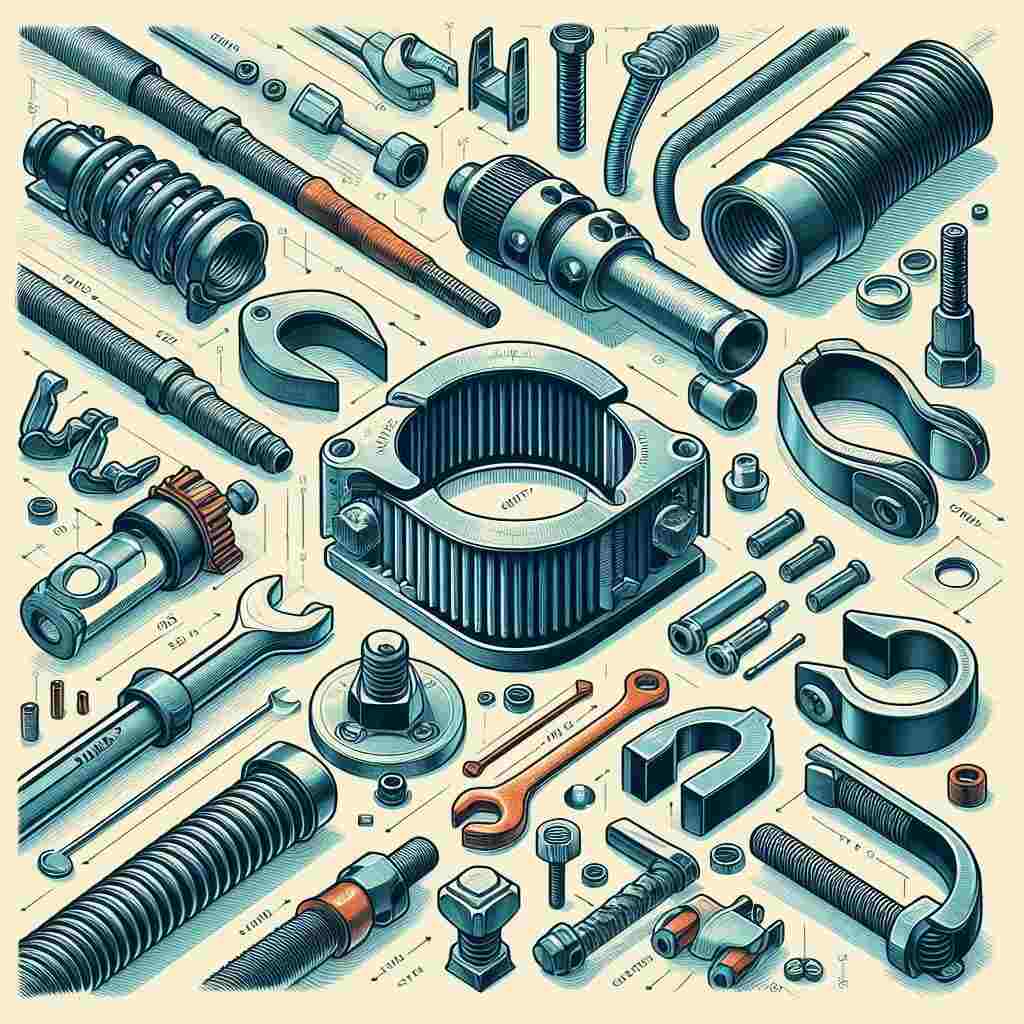

Anatomy of a Strut Clamp

Clamp Body

This is the visible part that hugs the pipe or conduit. Depending on design it may be a simple metal band, a split hinge, or a U-shaped bracket.

Fasteners (Bolts, Nuts, Channel Nuts)

Most strut clamps connect to the channel using channel nuts (slotted nuts that slide into the strut) plus bolts and washers. Other systems use U-bolts or special clips. The quality of these fasteners determines how secure and vibration-proof the assembly will be.

Cushions and Liners

Rubber or polymer liners protect pipe finishes, reduce vibration, and provide electrical isolation. For chilled water or sensitive conduits, these liners are a small investment that prevents big problems later.

Common Types of Strut Clamps

There’s no one-size-fits-all. Here are the types you’ll run into most often.

Two-Bolt (Two-Hole) Strut Clamp

A common workhorse: two-bolt clamps give solid lateral and vertical support and attach directly to the strut channel with channel nuts and bolts. Great for straight runs and heavier pipes.

U-Bolt Strut Clamp

U-bolts wrap around the pipe and thread into a plate that mounts to the strut. They’re quick and versatile—good for retrofits where you can’t slide a channel nut in from the end.

Cushioned / Rubber-Lined Pipe Clamp

Perfect for pipes that need protection or vibration damping. The rubber lining grips the pipe and prevents metal-on-metal contact.

Hinged / Split (Clamshell) Clamp

These have a hinge on one side and a bolt on the other so you can clamp around an existing line without dismantling the run. Time-saver for maintenance jobs.

Swivel / Adjustable Clamp

Used when angular adjustments or different mounting orientations are required. Useful in cramped spaces or when pipes must be offset.

Materials & Finishes

Material choice affects durability, cost, and where the clamp can be safely used.

Stainless Steel

Best for corrosive or outdoor environments. It’s pricier but will last far longer than plain steel in marine or chemical settings.

Galvanized / Zinc-Plated

A cost-effective middle ground. Hot-dip galvanized items resist rust well and are common in HVAC and general construction.

Polymer or Rubber Coatings

These reduce vibration, protect pipe finishes, and improve grip. Used on lined clamps and cushions.

Sizing and Compatibility

Matching Pipe O.D. and Clamp I.D.

Always match the clamp inner diameter to the pipe’s outside diameter. A loose clamp won’t support properly; an oversized clamp can compress and damage piping.

Strut Channel Profiles

Strut channels come in different widths and slot patterns. Make sure the clamp’s mounting hardware (channel nut size, U-bolt plate) is compatible with your channel profile.

How to Choose the Right Strut Clamp

Load & Spacing

Ask: How much weight will the clamp carry, and how far apart should supports be? For heavier lines, use more supports and clamps rated for the load.

Environmental Factors

Is the installation indoors, outdoors, seaside, or near chemicals? Choose stainless or special coatings for aggressive environments.

Vibration and Thermal Movement

If a pipe will vibrate or expand and contract, use cushioned clamps or clamps designed to allow limited movement — rigid clamping can transfer stress into the pipe.

Installation: Step-by-Step

Tools Required

- Socket or wrench set

- Screwdriver (for some clamps)

- Tape measure

- Level

- Torque wrench (recommended for critical installs)

- Safety equipment (gloves, eye protection)

Stepwise Procedure

- Plan your spacing: Determine support intervals based on pipe material and load.

- Measure and mark: Mark channel positions and pipe heights.

- Install channel nuts: Slide channel nuts into strut channel at the desired positions.

- Position clamp: Place clamp around the pipe or conduit. If using hinged clamps, close the hinge.

- Attach fasteners: Add bolt, washer, and nut through the clamp into the channel nut. Hand-tighten first.

- Level and align: Ensure the pipe is straight and properly supported.

- Torque to spec: Tighten bolts to a secure—but not excessive—level. If you don’t have a published torque spec, tighten until snug and then slightly more; avoid over-tightening which can deform metal or crush rubber liners.

- Check: Do a final inspection for alignment, clearance, and secure fastening.

Applications & Industries

Strut clamps are everywhere: mechanical HVAC, plumbing, electrical conduit runs, solar arrays, data centers, industrial piping, and more. Anytime you need modular, adjustable support, strut clamps are likely the right tool.

Benefits of Using Strut Clamps

Why choose strut clamps? They’re fast to install, flexible (repositionable), compatible with a wide range of accessories, and cost-effective. Think of them as the modular shelving system of industrial support — rearrangeable and practical.

Common Mistakes & How to Avoid Them

- Wrong material for the environment: Avoid rust surprises—choose corrosion-resistant finishes where needed.

- Over-tightening: Don’t crush liners or deform pipes. Tighten to secure, not to strip.

- Ignoring thermal expansion: Leave room for movement on long runs to prevent binding.

- Insufficient supports: Too few clamps leads to sag and stress. Follow spacing guidelines.

- Mismatched channel nuts or bolts: Verify hardware matches channel profile and clamp design.

Maintenance & Inspection Tips

Inspect clamps periodically — look for rust, worn cushions, loose bolts, and deformation. Re-torque bolts after initial system startup. Replace rubber liners exposed to oils or chemicals. A little maintenance prevents big rework.

Cost Considerations & Where to Buy

Strut clamps are available from electrical and plumbing supply houses, industrial distributors, and large online marketplaces. Prices scale with material and complexity: basic zinc-plated two-bolt clamps are inexpensive, while stainless, cushioned, or swivel variants cost more. Buy the best material budget allows for critical locations — it’s cheaper than premature replacement.

Environmental & Safety Considerations

Select clamps with appropriate corrosion resistance and fire safety ratings if needed. Avoid materials that will chemically react with the piping or environment. For seismic zones, use approved seismic-rated clamps and follow local code requirements.

Conclusion

A strut clamp may seem like a tiny, forgettable bit of hardware — but pick the wrong one and a small oversight can become a big problem. The right clamp improves safety, reliability, and serviceability. By understanding types, materials, sizing, and proper installation, you’ll make smarter choices on the job and avoid common pitfalls. Strut clamps are simple by design but pivotal in performance — treat them like the small but mighty components they are, and your systems will thank you.

FAQs

1. What is the difference between a strut clamp and a regular pipe clamp?

A strut clamp is specifically designed to mount to a strut channel (using channel nuts, U-bolts, or plates), while a regular pipe clamp may attach to walls, hangers, or other supports. Strut clamps are modular and optimized for channel systems.

2. Can I use any clamp material outdoors?

Not always. For outdoor or corrosive environments, choose stainless steel or hot-dip galvanized clamps. Plain steel without protective coating will rust quickly outdoors.

3. How often should I inspect strut clamps?

Inspect during installation, after initial startup, and periodically—annually for most systems, more frequently in harsh environments or critical services.

4. Are cushioned clamps necessary?

Cushioned (rubber-lined) clamps are recommended when you need to protect pipe finishes, reduce vibration, or electrically isolate the pipe from the clamp.

5. Can strut clamps support heavy piping?

Yes—when you choose clamps rated for the load and use appropriate spacing and multiple supports. For very heavy pipes, consult load tables and structural guidance.

6. What is the best way to allow for thermal expansion?

Use sliding supports or clamps that permit longitudinal movement at sliding points, and leave expansion joints or offsets where needed. Avoid rigid clamping at every support.

7. Are strut clamps reusable?

Many are reusable, especially metal clamps. Hinged or split clamps are particularly maintenance-friendly for reuse. Replace rubber liners if worn.

8. How do I choose clamp spacing?

Spacing depends on pipe material and diameter. As a rule of thumb, smaller-diameter pipes need closer spacing; heavier lines need more frequent supports. When in doubt, follow manufacturer guidelines.

9. Do I need special channel nuts for certain clamps?

Some clamps require specific channel nut types or sizes for secure fit. Verify compatibility between the clamp and the channel profile before purchasing.

10. Where can I find seismic-rated strut clamp solutions?

Seismic-rated clamps and accessories are available from specialized industrial and HVAC suppliers. For seismic installations, follow local codes and use hardware certified for seismic use.