Strut Strap: Guide to Choosing, Installing and Using Strut Straps

What is a Strut Strap?

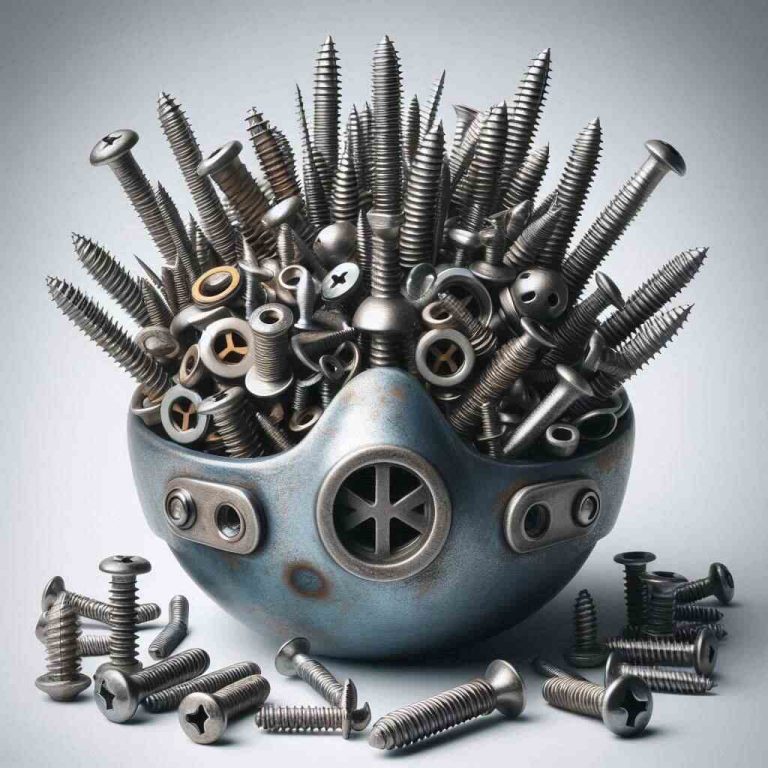

Imagine strut channels as the backbone of a mechanical or electrical support system, and strut straps as the hands that hold pipes, conduit, or tubing firmly in place. A strut strap is a metal band or clamp designed to secure conduit, pipe, or tubing to strut channels or directly around the pipe. They keep lines organized, safely supported, and protected from vibration or movement.

Strut Strap vs. Pipe Strap vs. Conduit Strap

While often used interchangeably, these terms have subtle differences. A pipe strap typically wraps around tubing and is often a simple U-shaped band; a conduit strap is sized and shaped for electrical conduit; and a strut strap is designed specifically to work with strut channels, often featuring captured nuts or offsets for easier installation.

Common Materials & Finishes

Strut straps come in several materials and finishes: stainless steel (for corrosion resistance), galvanized steel (electro-galvanized or hot-dip), and PVC-coated steel for added protection. The choice depends on the environment — stainless for corrosive or coastal conditions, galvanized for indoor use, and PVC-coated for added durability.

When to Pick Which Finish

- Coastal or chemical-exposed sites → Stainless steel

- General indoor/industrial → Galvanized steel

- Areas prone to abrasion or moisture → PVC-coated steel

Types of Strut Straps

One-piece Straps

A single stamped piece that bolts directly to the strut. Simple, quick, and usually cost-effective.

Two-piece and Offset Straps

Two-piece straps feature a saddle and a band, ideal for tight spaces. Offset straps are bent to provide clearance for obstacles, making them perfect for crowded installations.

Universal/Captive-Nut Designs

These straps include a built-in nut that slides into the strut channel, allowing faster, one-handed installation and reducing dropped hardware.

Sizes, Dimensions, & Load Considerations

Selecting the correct size is crucial. Match the internal diameter of the strap to the pipe or conduit, and ensure the strap width and thickness meet load requirements. Follow manufacturer load charts to prevent sagging or over-stressed supports.

How to Install a Strut Strap (Step-by-step)

Tools You’ll Need

- Ratchet and socket or nut driver

- Torque wrench for critical installations

- Measuring tape

- Metal snips (if adjustments are needed)

Installation Steps

- Measure the pipe or conduit diameter and select the right strap.

- Position the strap so it sits squarely over the pipe.

- Engage the strap nut with the channel or thread the bolt through the strap and tighten.

- Use a torque wrench to secure the bolt to the recommended specification.

- Space multiple supports according to manufacturer guidelines to avoid sagging.

Common Installation Mistakes

- Using the wrong diameter strap

- Over-tightening and deforming the pipe or conduit

- Ignoring environmental factors

- Spacing supports too far apart

Applications & Use Cases

Electrical Conduit and Cable Support

Strut straps are essential for keeping electrical conduit runs neat, supported, and code-compliant.

Plumbing, HVAC, and Mechanical Piping

Small plumbing lines, condensate drains, and service piping often rely on strut straps for modular and flexible support.

Automotive vs. Building Strut Straps

Automotive strut clamps are designed for vehicle suspension systems, not building support. Strut straps for construction support pipes and conduit, not shock absorbers.

Code, Standards & Safety

Check local electrical or mechanical codes before installation. Many straps carry certifications, and adhering to torque guidelines ensures a secure, safe system. Proper installation prevents rattling, pipe deformation, or structural failure.

Selecting the Right Strut Strap: Buyer’s Checklist

- Measure the pipe or conduit and strut channel

- Determine the environment (indoor, outdoor, coastal)

- Choose the correct material and finish

- Pick the strap type (one-piece, two-piece, offset, captive-nut)

- Verify load and span requirements

- Consider ease of installation

Maintenance, Inspection & Troubleshooting

Inspection Points

- Check for corrosion or pitting

- Ensure bolts are tight and hardware is intact

- Look for deformed or bent straps

- Verify proper support spacing

Repair vs. Replace

Replace straps that are corroded, bent, or damaged. Tighten loose hardware to specification but do not continue using failing straps.

DIY vs. Hiring a Pro

For small, non-critical runs, a homeowner can install strut straps. For commercial projects, engineered spans, or code-sensitive systems, it’s best to hire a professional.

Cost, Where to Buy, and Brand Notes

Strut straps are available from electrical distributors, industrial supply stores, and hardware stores. Prices vary based on material, type, and design complexity. Reputable brands ensure quality and proper load ratings.

Common Mistakes to Avoid

- Using the wrong diameter strap

- Ignoring load charts and exceeding spans

- Mixing incompatible metals in corrosive environments

- Forgetting thermal expansion considerations

Sustainability & Recycling Options

Steel strut straps are recyclable. Choosing durable materials reduces replacement cycles, and some suppliers offer products made from recycled content for eco-conscious projects.

Conclusion

Though small and simple in appearance, strut straps play a critical role in keeping piping and conduit safe, secure, and organized. Selecting the right type, material, and installation method ensures a long-lasting and reliable system. Whether you’re a DIY enthusiast or a professional installer, understanding strut straps will save time, effort, and potential headaches.

Frequently Asked Questions (FAQs)

1. What is the main purpose of a strut strap?

It secures conduit, pipe, or tubing to a strut channel or around a pipe, keeping it stable and organized.

2. Can I use a regular pipe strap instead?

It may work in some cases, but a strut strap is designed for strut channels and often installs more securely.

3. Are strut straps rated for load?

Yes, many come with load charts specifying allowable spans and weight limits.

4. Which material is best for outdoor or coastal environments?

Stainless steel is preferred for high-corrosion areas.

5. How often should I inspect strut straps?

Annually for outdoor or critical systems; otherwise, inspect during routine maintenance.

6. Can strut straps be reused?

Only if they are undamaged and corrosion-free.

7. What is an offset strap?

A strap bent to create clearance, allowing pipes or conduit to avoid obstacles.

8. Do I need a torque wrench for installation?

For light DIY projects, it’s optional; for critical or code-driven installs, it is recommended.

9. Where can I buy quality strut straps?

Electrical distributors, industrial suppliers, and hardware stores carry a wide selection.

10. Are there alternatives to strut straps?

Yes, including beam clamps, custom brackets, and hanger rods, depending on the project needs.