Why is Steel Used in Screwdrivers in Ferrous Materials

If you’ve ever tried to drive a stubborn screw into a steel bracket or pry a rusted fastener out of a cast-iron plate, you already know that screwdrivers take a beating. Working with ferrous materials (metals that contain iron — think mild steel, stainless steel, cast iron) calls for tools that can stand up to abrasion, impact, and occasional abuse. So why is steel the go-to material for screwdrivers? Short answer: because steel can be engineered to be both hard and tough, affordable, and easy to make into precise tips that match the fastener. Let’s unpack that.

The basic demands on screwdriver materials

Before picking a material, we should list what a screwdriver must do when working with ferrous materials.

Hardness and wear resistance

The tip must resist abrasion and keep its shape when it contacts hardened screw heads. If the tip is too soft it will round off and slip.

Toughness and impact resistance

Screwdrivers get hammered, twisted, dropped. The metal must avoid chipping or snapping when subjected to impact and torsion.

Corrosion resistance

Often tools are used in dirty, wet, or salty environments. Rusty tips are weak tips. Some resistance to corrosion (or a protective finish) helps longevity.

Magnetic behavior and conductivity

For many jobs, a slightly magnetic tip helps hold screws. Also, for electrical work you sometimes want non-magnetic or insulated tools — but for general ferrous work magnetism is often a small advantage.

Steel: a near-perfect match for the job

Steel sits in a sweet spot of properties, cost, and manufacturability.

The iron-carbon family and tunable properties

Steel is iron with controlled amounts of carbon and other alloying elements. By adjusting composition and processing, manufacturers can tune properties across a wide range: soft and ductile for handles, very hard and wear-resistant for tips. Think of steel like a recipe where a pinch more carbon, a dash of chromium, and the right oven settings (heat treatment) produce exactly the texture you need.

Heat treatment — the secret sauce

One big advantage of steel is that heat treatment (quenching and tempering, case hardening, nitriding) can dramatically change hardness and toughness. You can harden the tip to resist wear while leaving the shank tough so the tool won’t snap — that gradient of properties is crucial for a durable screwdriver.

Common steels and alloys used in screwdriver tips

High-carbon steels

Simple, high-carbon steels are commonly used and can be hardened to a fine, sharp, wear-resistant edge. They’re affordable and take heat treatment well.

Tool steels and S2

S2 tool steel and other shock-resistant tool steels are common for impact-rated bits and heavy-duty drivers. These steels are formulated to withstand torsion and repeated impacts without fracturing.

Chromium-vanadium and stainless options

Cr-V (chromium-vanadium) steels add toughness and corrosion resistance; many hand tools advertise “Cr-V” for durability. Stainless steels give excellent corrosion resistance but can be trickier to heat treat to very high hardness — that’s why you don’t always see stainless tips on heavy-duty bits unless they’re specially alloyed.

Manufacturing techniques that make steel work

Forging, machining, and finishing

Good screwdrivers start with the right shaping: forging the blank for strength, then precision machining the tip to match screw geometries. A smooth, accurate tip fits the fastener and reduces “cam-out” (slipping).

Induction hardening and case hardening

To get a hard tip and a tough body, manufacturers use localized hardening methods. Induction hardening rapidly heats just the tip and then quenches it, producing a hard outer layer with a tougher core. Case hardening (carburizing) packs extra carbon into the surface to raise surface hardness while keeping core ductility.

Surface coatings and platings

Black oxide, phosphate, chrome plating, or nitrocarburizing help reduce corrosion and surface wear. Coatings also change friction and appearance, and they’re a cheap way to prolong life.

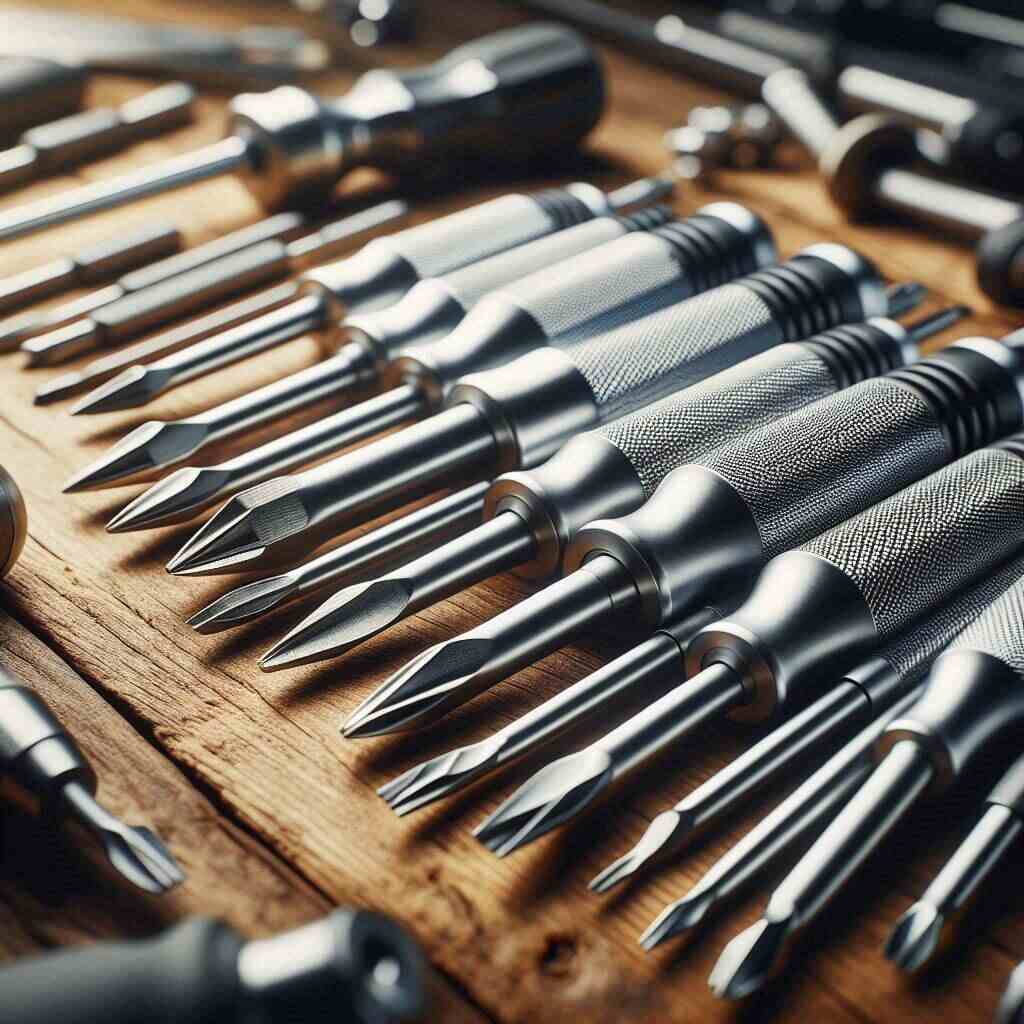

Design considerations for screwdriver tips

Tip geometry and fit

Even the best steel will fail if the tip geometry is wrong. A precise fit between driver and screw head spreads load across more metal and reduces tip wear and screw rounding. That’s why quality drivers are sized and finished tightly.

Surface finish and edge retention

A polished, well-finished tip bites cleaner and lasts longer. Microscopic burrs or uneven surfaces speed up wear and make slipping more likely.

Magnetized tips: pros and cons

Magnetizing a steel tip helps hold screws in place — especially tiny ones. But magnetism can be a nuisance for electronics or certain measurement instruments. Because steel is ferromagnetic, it’s easy to magnetize (or demagnetize) compared to non-ferrous alternatives.

Why non-steel alternatives are less common for ferrous work

Soft metals (brass, aluminum) — too soft

Brass or aluminum screwdrivers are intentionally soft and used where sparking must be avoided or where you’re working with delicate finishes. But against ferrous screws they deform and wear fast. Not suitable for heavy work.

Ceramics and composites — brittle or costly

Ceramic or composite tools can be non-magnetic and very hard, but they’re brittle and expensive. Not practical for everyday screwdriver tasks where impact resistance matters.

Specialty alloys for special jobs

There are cases where non-steel materials win: beryllium-copper or aluminum bronze tools are used in explosive atmospheres because they’re non-sparking. Insulated screwdrivers use non-conductive sleeves to protect against shocks. But for general use on ferrous materials, steel’s balance of properties and cost is tough to beat.

Standards, testing, and quality markers

Reputable tool makers test hardness, torsional strength, and tip fit. Standards from organizations like ISO and ANSI set expectations for dimensions and performance. Look for tools that list material (S2, Cr-V), hardness ranges, and impact ratings — those are practical signs of quality.

Practical tips: choosing the right steel screwdriver for ferrous materials

- Match tip to screw: Correct size and profile reduce wear.

- Pick the right steel: For heavy duty, choose S2 or Cr-V tool steel; for general-purpose, a hardened carbon/Cr-V driver is fine.

- Consider coating: If you work outdoors or around humidity, look for black oxide or phosphate finishes.

- Magnetized vs. non-magnetized: For assembly work, magnetized tips save time; for electronics, avoid magnetism.

- Insulated or non-sparking when needed: Use specialized tools for live circuits or explosive atmospheres.

Care, maintenance, and when to replace a screwdriver

Keep tips clean, avoid using screwdrivers as chisels or pry bars, and store tools dry. If the tip is rounded, chipped, or the shank is bent, replace the tool — a damaged screwdriver does more harm than good and ruins screw heads.

Environmental, cost, and safety considerations

Steel is highly recyclable — old drivers are easier to recycle than composite tools. While premium alloyed steels cost more upfront, they last longer and often give better value over the tool’s life. Safety-wise, a strong, well-made steel driver reduces slip incidents and stripped screws.

Conclusion

So, why is steel used in screwdrivers for ferrous materials? Because steel answers the core demands: it can be made very hard where the tip meets fasteners, while staying tough enough to resist impact and torsion; it’s affordable, easy to manufacture precisely, and plays nicely with ferrous screws (including being magnetizable when you want it to be). Alternatives exist for special cases, but for the everyday tasks of fastening and unfastening iron-based materials, steel remains the practical, engineered, and economical winner.

FAQs

Q1: Can stainless steel screwdrivers be as hard as other steel screwdrivers?

A1: Some stainless alloys can be heat treated to reasonable hardness, but many stainless grades trade off maximum hardness for corrosion resistance. Specialized stainless tool steels exist but are less common and usually more expensive.

Q2: What is S2 steel, and why do manufacturers mention it?

A2: S2 is a shock-resistant tool steel commonly used in screwdriver bits and impact drivers. It’s formulated for toughness under torsion and repeated impacts — ideal for heavy-duty screwdriving.

Q3: Will a magnetic tip damage electronics?

A3: A small magnetized screwdriver tip is unlikely to damage most modern electronics, but sensitive magnetic storage or certain sensors can be affected. Use nonmagnetic or demagnetized tools when in doubt.

Q4: Why do some screwdriver tips have a black finish?

A4: Black oxide, phosphate, or similar finishes reduce corrosion, lower glare, and offer a slight increase in wear resistance. They also help reduce friction between the tip and screw.

Q5: How hard should a screwdriver tip be?

A5: Manufacturer specs vary, but hardened tips typically range in the high mid-hardness values appropriate for tool steels. The goal is a balance: hard enough to resist wear, but not so brittle that the tip chips.

Q6: Can you re-sharpen or re-finish a worn screwdriver tip?

A6: Minor reshaping can be done carefully with a file or grinder, but heat-treated tips can lose hardness if you remove too much material or overheat them. Often replacing the worn driver or bit is safer and cheaper.

Q7: Are chrome-vanadium screwdrivers better than plain carbon steel ones?

A7: Cr-V steels usually offer better toughness and some added corrosion resistance compared to basic carbon steels. They’re a common, reliable choice for hand tools.

Q8: When should I choose a non-steel screwdriver?

A8: Choose non-steel (e.g., brass, beryllium-copper, or composite) when you need non-sparking tools, non-magnetic behavior, or electrical insulation. For heavy ferrous work, steel is normally preferable.

Q9: Do insulated screwdrivers use different steel?

A9: The metal core is often standard hardened steel, but insulated screwdrivers have thick nonconductive handles and sleeves tested for electrical safety. Don’t assume a brightly colored handle means it’s properly insulated.

Q10: How can I tell if a screwdriver is made from quality steel?

A10: Look for maker specifications (S2, Cr-V, hardness ratings), an accurate tip profile, solid manufacturing (no loose handles), and reviews or standards compliance. A quality driver will feel sturdy and maintain tip shape under normal use.