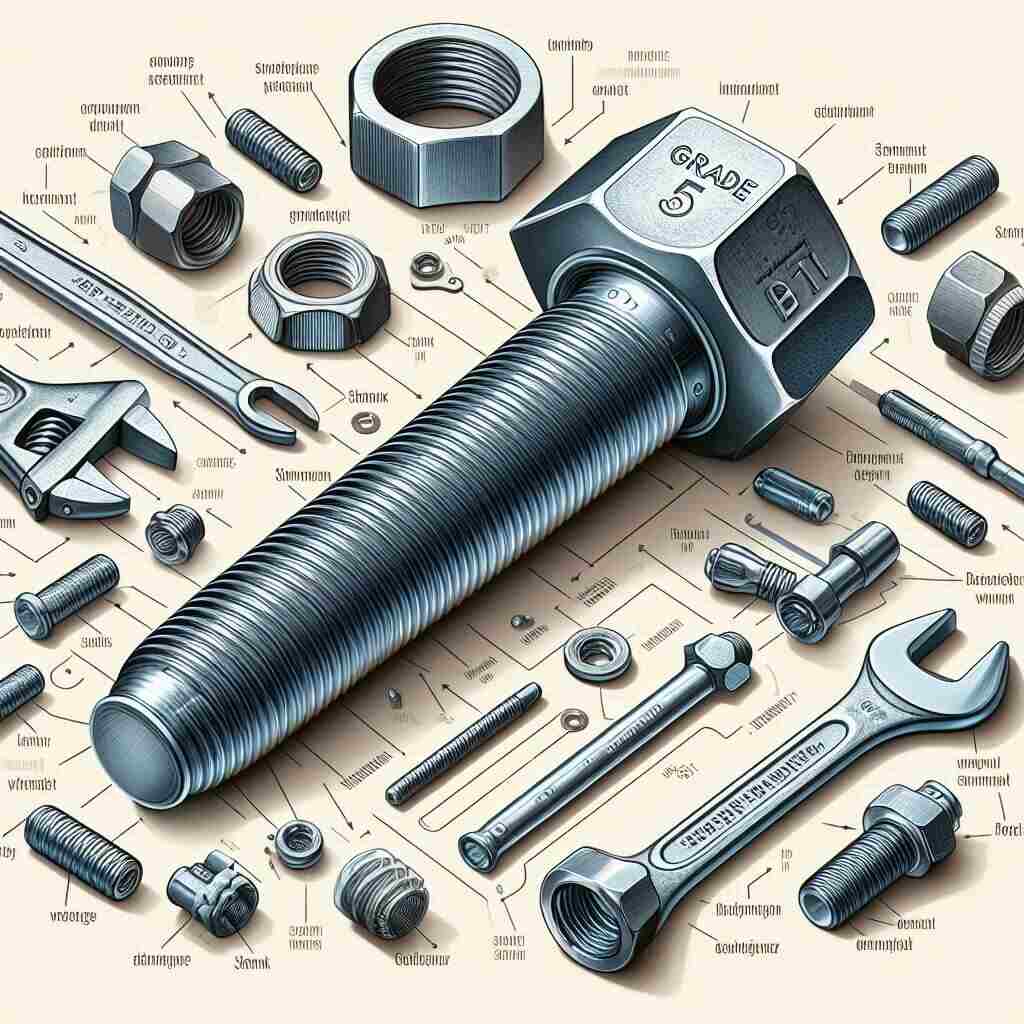

Grade 5 Bolt: Everything You Need to Know

When it comes to bolts, not all are created equal. If you’ve ever worked on a car, built furniture, or tinkered with machinery, you’ve probably come across Grade 5 bolts. But what makes them so special? In this article, we’ll break down everything about Grade 5 bolts, from what they are to how to use them effectively.

What is a Grade 5 Bolt?

Understanding Bolt Grades

Bolts are classified into grades based on their strength and material properties. Grade 5 bolts are medium-strength bolts, widely used in both automotive and construction projects. They’re stronger than Grade 2 bolts but not as strong as Grade 8, making them a versatile choice for many applications.

The Material Behind Grade 5 Bolts

Grade 5 bolts are typically made from medium carbon steel that is quenched and tempered. This process improves both the strength and durability of the bolt, allowing it to handle higher stress than standard bolts. Their material composition is what gives them a perfect balance of toughness and reliability.

Key Features of Grade 5 Bolts

Tensile Strength and Hardness

Grade 5 bolts are designed to handle a tensile strength of about 120,000 PSI. This means they can withstand a lot of pulling force without breaking. They’re also moderately hard, which helps prevent stripping or wear over time.

Threading and Dimensions

These bolts usually come with coarse threads, though fine threads are available for precision applications. Coarse threading is preferred in most situations because it’s easier to assemble and offers better resistance to vibrations.

Coating and Corrosion Resistance

Many Grade 5 bolts come with zinc plating or other protective coatings to resist corrosion. However, in extremely harsh environments, you may need stainless steel or specially coated bolts for extra protection.

Common Uses of Grade 5 Bolts

Automotive Applications

Grade 5 bolts are a favorite in the automotive world. They’re used for engine components, suspension parts, and chassis assemblies. Their balance of strength and flexibility makes them perfect for vehicles that endure stress but need some give to avoid breaking.

Construction and Heavy Machinery

In construction, these bolts secure structural elements like beams, machinery mounts, and heavy equipment. They are strong enough for critical load-bearing applications without the premium cost of Grade 8 bolts.

DIY Projects and Home Repairs

For DIY enthusiasts, Grade 5 bolts are a go-to. Whether you’re building a shed, assembling a deck, or fixing a large appliance, these bolts offer the strength and reliability needed for home projects.

Advantages of Using Grade 5 Bolts

Durability and Strength

Grade 5 bolts provide a reliable combination of strength and flexibility, reducing the risk of snapping under stress. They can handle most applications without needing to upgrade to a higher grade.

Cost-Effectiveness

They’re cheaper than Grade 8 bolts but stronger than Grade 2, making them a cost-effective option for both professionals and hobbyists.

Easy Availability

Grade 5 bolts are widely available at hardware stores, automotive shops, and online retailers. This accessibility makes them a convenient choice for anyone needing durable fasteners.

How to Identify a Grade 5 Bolt

Head Markings and Symbols

The easiest way to identify a Grade 5 bolt is by looking at the three radial lines on the head. These lines indicate its grade and strength, so you can quickly differentiate it from other bolts.

Comparing with Other Grades (Grade 2 & Grade 8)

- Grade 2: Low strength, no head markings, often used in light applications.

- Grade 5: Medium strength, three lines on the head, versatile and reliable.

- Grade 8: High strength, six lines on the head, used for heavy-duty or high-stress applications.

How to Properly Install Grade 5 Bolts

Tools You’ll Need

To install Grade 5 bolts, you’ll typically need a wrench, socket set, or torque wrench. Using the right tools ensures proper tightening and reduces the risk of damage.

Torque Specifications

Torque is crucial. Over-tightening can strip threads or break the bolt, while under-tightening can lead to loosening. Most Grade 5 bolts have manufacturer-recommended torque values, so always check before installation.

Tips for Longevity

- Use anti-seize lubricant on threads for easier removal later.

- Avoid mixing metals to prevent galvanic corrosion.

- Inspect bolts regularly in high-stress applications like vehicles or machinery.

Common Mistakes to Avoid

Over-Tightening

One of the biggest mistakes is over-tightening, which can cause the bolt to snap. Always follow torque guidelines.

Using in Incorrect Applications

While Grade 5 bolts are strong, they aren’t suitable for extreme high-stress environments like some engine components. Knowing the limits is essential.

Grade 5 Bolts vs. Grade 8 Bolts

Strength Differences

Grade 8 bolts are stronger and harder than Grade 5, capable of handling heavier loads. However, their rigidity makes them less forgiving in situations that require slight flex.

Cost and Availability

Grade 8 bolts are more expensive and sometimes harder to find, making Grade 5 a practical alternative for many projects.

Choosing the Right Bolt for the Job

Always assess the load and stress requirements. For most automotive and construction projects, Grade 5 offers the ideal balance of strength and cost.

Maintaining Grade 5 Bolts

Regular Inspections

Check for signs of corrosion, wear, or loosening. Catching issues early prevents accidents and costly repairs.

Lubrication Tips

Applying anti-seize compounds or light grease can prevent rust and make future removal easier. Avoid heavy oils that attract dirt.

Purchasing Tips

Choosing Reputable Brands

Not all bolts are created equal. Opt for certified manufacturers to ensure you get genuine Grade 5 bolts with proper strength and durability.

Bulk vs. Single Purchase

Buying in bulk can save money if you need many bolts. For small projects, single or small packs are more convenient and cost-effective.

Environmental Considerations

Weather and Temperature Effects

Extreme temperatures and humidity can affect bolt integrity over time. Zinc-plated or stainless options help mitigate corrosion risks.

Rust Prevention Techniques

- Store bolts in a dry, cool place.

- Use coatings or sprays for extra protection in outdoor applications.

- Regularly inspect and replace rusty bolts.

Interesting Facts About Grade 5 Bolts

Historical Development

Grade 5 bolts became popular in the mid-20th century, offering a medium-strength alternative to basic hardware. They revolutionized both automotive and construction industries.

Industry Standards

Grade 5 bolts meet ASTM and SAE standards, ensuring consistent performance across applications worldwide.

Conclusion

Grade 5 bolts are the unsung heroes of fasteners. They strike the perfect balance between strength, flexibility, and affordability, making them suitable for a wide range of applications—from cars to construction to DIY projects. By understanding their features, installation tips, and proper maintenance, you can ensure they perform reliably for years.

FAQs

- What is the difference between Grade 5 and Grade 8 bolts?

Grade 8 bolts are stronger and harder, suitable for high-stress applications, while Grade 5 bolts offer medium strength and more flexibility. - Can Grade 5 bolts be reused?

Yes, if they show no signs of wear, corrosion, or deformation. Always inspect before reuse. - Are Grade 5 bolts suitable for outdoor use?

They can be used outdoors if coated or plated for corrosion resistance. - What tools are best for installing Grade 5 bolts?

A torque wrench, socket set, and proper-sized wrenches ensure safe and secure installation. - How do I know the torque specification for a Grade 5 bolt?

Manufacturer guidelines or SAE standards provide recommended torque values based on bolt diameter and thread type. - Can I use Grade 5 bolts for automotive engines?

Yes, for many components, but check for specific engine requirements, as some high-stress parts may need Grade 8 bolts. - What does the marking on a Grade 5 bolt head mean?

Three radial lines indicate Grade 5, signifying medium tensile strength and hardness. - How long do Grade 5 bolts last?

With proper installation and maintenance, they can last decades, especially in non-extreme environments. - Are Grade 5 bolts stronger than stainless steel bolts?

It depends on the stainless steel type, but Grade 5 bolts generally offer higher tensile strength than standard stainless steel bolts. - Where can I buy high-quality Grade 5 bolts?

Hardware stores, automotive supply shops, and certified online retailers carry authentic Grade 5 bolts.